Ultra-detailed, exceptionally precise

Complex geometries at lightspeed

Ultra-precise

Cost-efficient

Lightning-fast

Precision beyond conventional limits

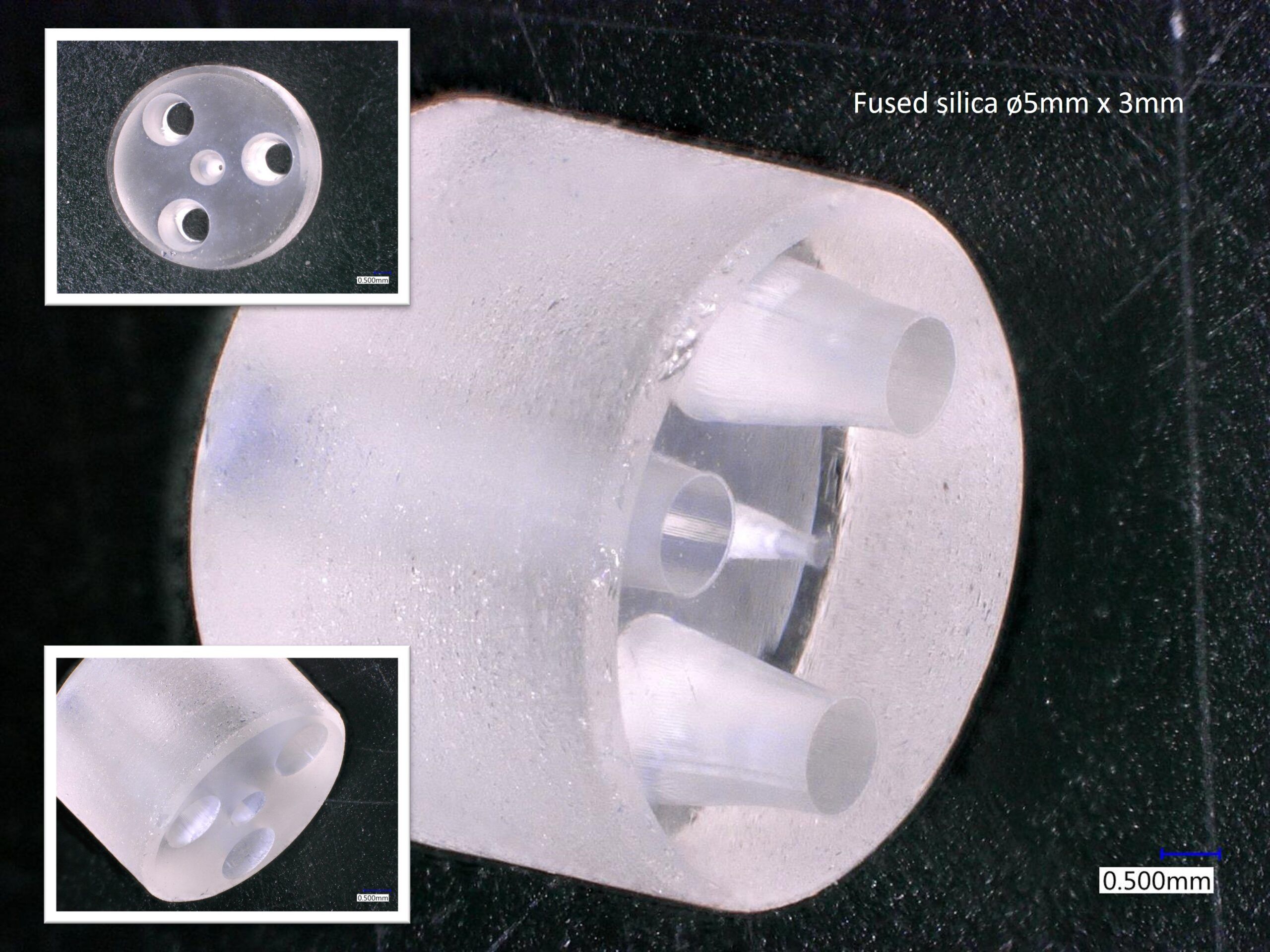

Our laser micromachining produces intricate structures from 5 to 500 microns. Features impossible with traditional tooling. Complex geometries, micro-channels, ultra-fine holes, and precision textures in virtually any material. No tooling required. Unlimited design freedom. Microscopic precision.

The result? Components that are smaller, lighter, stronger, and more efficient than traditional methods can achieve.

Breakthrough performance. Lightning-fast delivery.

Advantages that deliver

- Next-level precision

accuracy that defies conventional limits - Minimal thermal damage

enhanced precision and quality - High reliability

eliminating failure costs before they happen - Excellent reproducibility

identical results, batch after batch - Universal capability

any material, any challenge

Laser micromachining

High-quality microlaser processing

Cutting, milling, drilling, structuring and perforating.

- Machining 0,003 mm to 0,05 mm

- Ultra short pulse

- Infrared to ultraviolet

- Cold ablation

- All materials

Micromachining silicone

micromachining quartz

Cold ablation

Cold ablation vaporizes material instantly without melting or burning. Perfect for glass, ceramics, diamond, and other materials that crack under thermal stress. Material simply disappears, leaving pristine surfaces behind.

Minimal thermal influence

High precision and accuracy

Create structures conventional methods can’t touch. Precision mechanical engineering and optical applications demand this level of accuracy.

Clean surfaces

Clean removal without residue, contamination, or waste. Surfaces ready for immediate use. No post-processing required.

Wear-free production

No tool contact means no wear, no replacement costs, no downtime. Sustainable precision that pays for itself.

Sublimation

Direct transition, netx-level precision. Sublimation skips the liquid phase entirely. Solid becomes gas instantly. Perfect for polymers, biological tissues, and delicate materials that conventional methods destroy. No melting. No burning. Just precise material removal.

Minimal thermal influence

Soft materials stay intact while achieving next-level precision. No heat stress, no deformation, no compromise on delicate structures.

High precision and accuracy

Create very complex structures with high precision. Critical in producing high-quality microelectronics and biomedical devices.

Clean surfaces

Clean elimination without residue or contamination. Surfaces ready for immediate use. No cleanup, no delays, no compromises.

Sustainable production

No tool contact means no wear, no replacement costs, no downtime. Sustainable precision that pays for itself.

Push beyond conventional limits

When conventional methods reach their limits, laser micromachining breaks through.

Ultra-precise features, zero tooling constraints, lightning-fast turnaround.

Ready to unlock micro-precision capabilities?