The perfect fusion

Precision bonding with minimal distortion, maximum strength

Accuracy

Cost-efficient

Fast

Fusion perfected

Precision heat creates permanent bonds

Transform separate components into unified assemblies through controlled fusion. Our lasers deliver exact heat placement, creating strong joints with next-level precision and minimal thermal impact.

Controlled depth. Perfect positioning. Permanent strength.

Welding advantages that deliver

- Minimal heat input

precision without distortion - Next-level accuracy

exact placement and penetration - Superior joint strength

superior quality - Production speed

high-volume capability unlocked

Minimal distortion,

maximum precision

High-strength connections with exceptional accuracy

Precision welding with reduced heat input. Joints that maintain structural integrity while minimizing distortion to near-negligible levels.

- Spot welding. Precise point connections

- Heat conduction welding. Up to 1 mm material thickness

Materials welded: Stainless steel • Titanium • Aluminum • Plastics

Advantages: Minimal heat-affected zone • Reduced distortion • High precision • Production speed

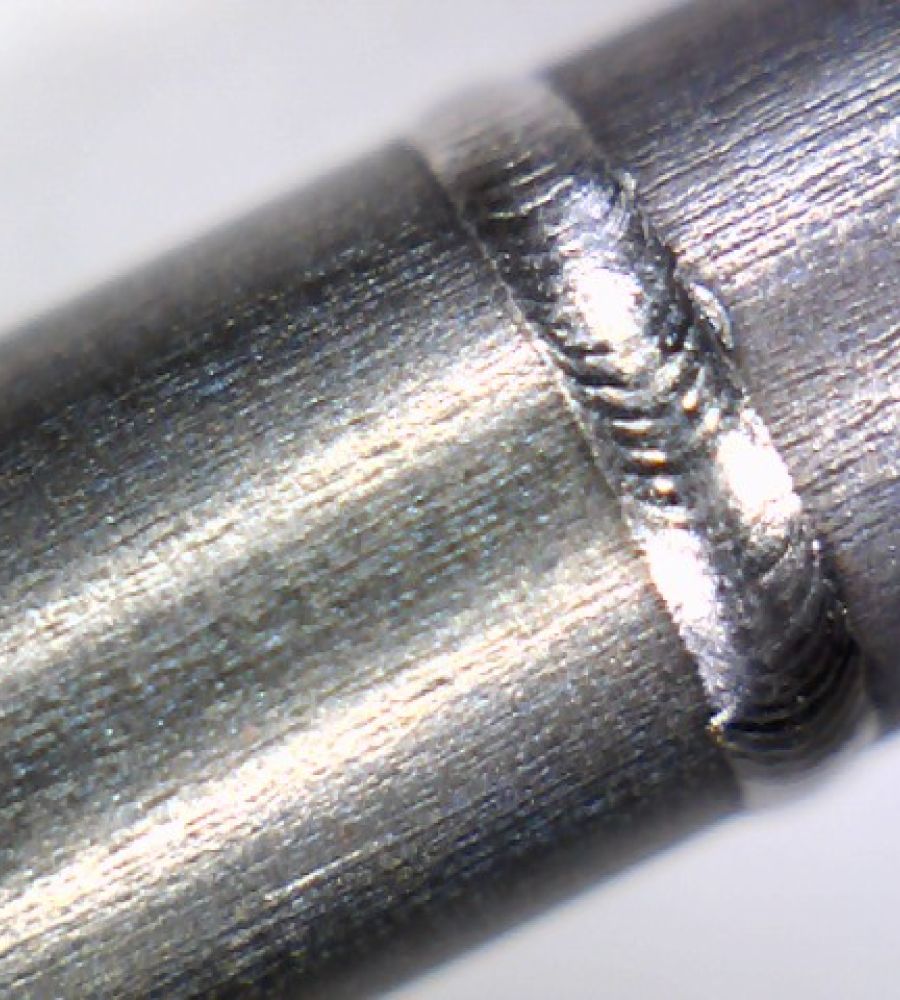

Welding complex geometries

Seam welding

Added material

Spot welding

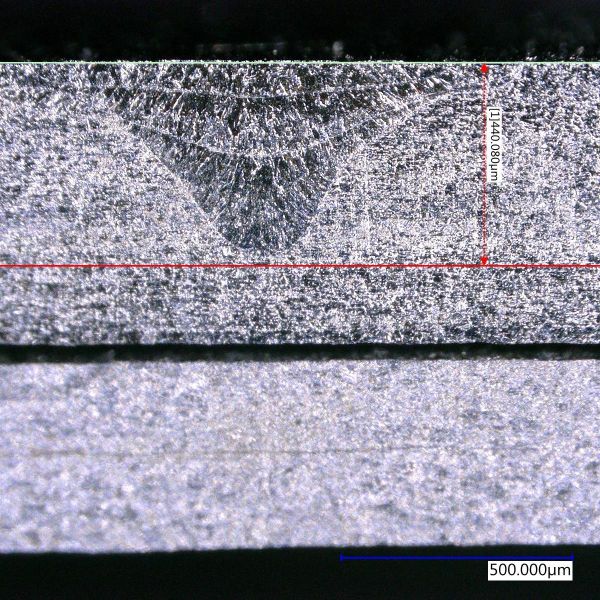

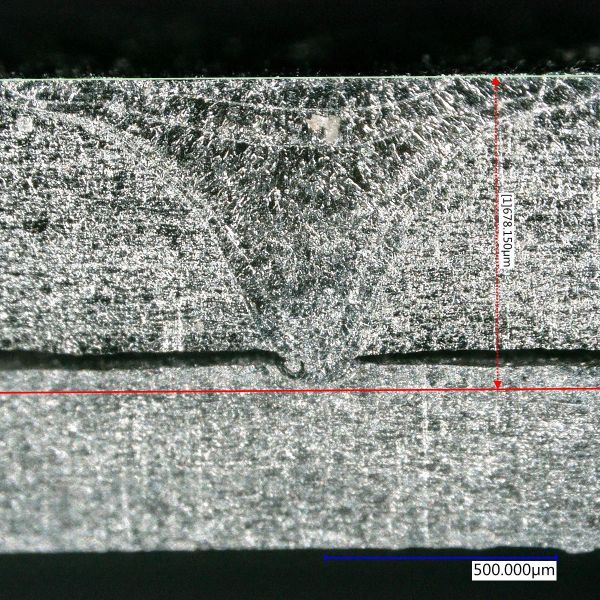

Cross section

Pure material fusion

minimal intervention

Clean welding often requires zero filler material. Just precise heat control that fuses materials perfectly. When enhancement is needed, our complete filler inventory optimizes every joint.

Low heat input. Surgical accuracy. Flawless fusion.

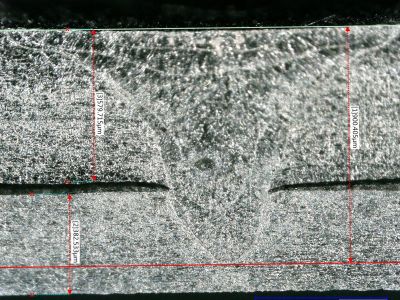

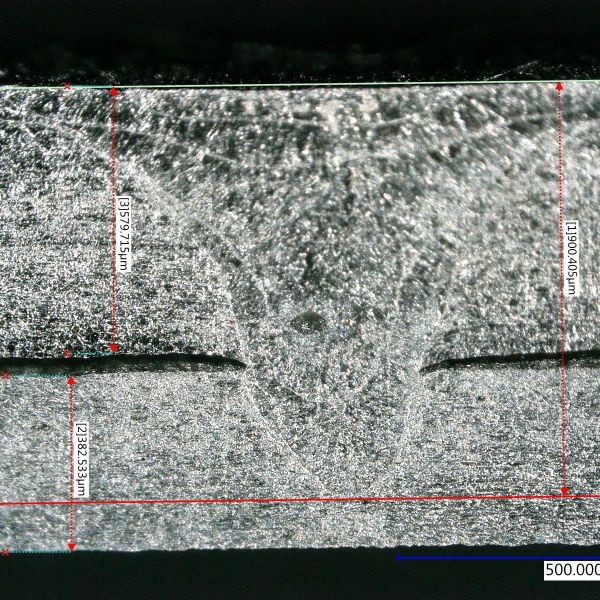

Weld depth verification

Cut-through testing reveals true penetration depth and fusion quality.

Visual confirmation that every weld meets structural requirements.

Welding depth | test 1

Welding depth | test 2

Welding depth | test 3

Need material-specific guidance?

Our Materials page breaks down weldability by material type.

Your roadmap to optimal welding parameters.

Solve your welding challenges

Complex geometries, exotic materials, zero-tolerance requirements?

We excel at welding applications that demand technical mastery.

Ready to tackle your most demanding projects?