Pioneers in laser technology

Advanced laser solutions for high-tech markets

Laser experts

Innovative

10.000+

Pioneers in

lasertechnology

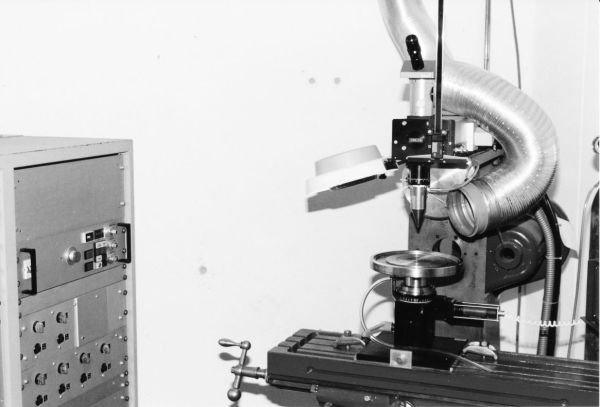

First laser setup in 1989

Masters in micromachining

For over four decades, we’ve been passionate pioneers in precision microlaser processing. What started as a vision to push the boundaries of what’s possible has grown into a trusted partnership with high-tech industries worldwide.

We take pride in our ability to transform complex challenges into breakthrough solutions—whether refining proven approaches or engineering entirely new possibilities. Our deep expertise spans aerospace, medical device, and advanced manufacturing, where precision isn’t just preferred, it’s essential.

Laser

innovations

Fascination with light

Light captivates us—not just as energy, but as infinite potential waiting to be unlocked. This fascination drives our relentless pursuit of what laser technology can achieve.

We believe true leaders never stop innovating. That’s why we’ve pioneered breakthrough laser disciplines over the decades, including our proud introduction of ultra-short pulse laser technology to material processing in 2008.

Each advancement stems from asking “what if?” and refusing to accept limitations. Light isn’t just our tool—it’s our inspiration.

State of the art

Precisely perfect

Every project is a masterpiece in the making—where precision meets complexity to create something extraordinary.

We take pride in transforming the most challenging production puzzles into elegant, innovative solutions.

Armed with cutting-edge technology and four decades of hard-earned expertise, we thrive on projects others consider impossible. Our deep knowledge in microlaser processing and materials isn’t just experience—it’s craftsmanship perfected.

From challenge

to solution

We’re going for gold

Excellence isn’t just our goal—it’s our obsession. Every single day, we pour our hearts into crafting solutions that don’t just work, but truly shine. We believe every challenge deserves a personal touch and relentless dedication.

Have a production puzzle that’s been keeping you up at night? We live for these moments. Challenge us with your toughest problems—because turning impossible into gold is what we do best.

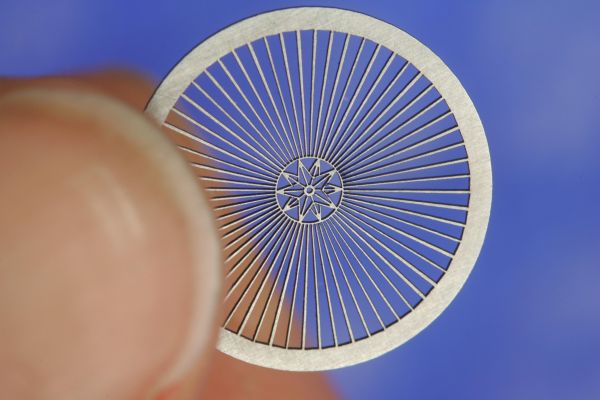

Excelling at the smallest level

We believe that the smallest details create the biggest breakthroughs. Our precision micromachining solutions empower customers to push boundaries, exceed expectations, and achieve technological excellence.

Together, we turn your boldest ideas into precision reality.

Helping to cure chronic diseases

Veldlaser is a development partner of RegMed XB, a collaboration between research institutions, governments, provinces, health funds and businesses for regenerative therapies for chronic diseases.

We manufacture specialized polymer structures for the production of valuable stem cells. Regenerative medicine focuses on repairing or replacing failing tissues or organs.

The goal is to offer hope to millions suffering from diseases such as type 1 diabetes, osteoarthritis, kidney and heart failure—giving them a chance at a higher quality of life.

We’re honored to contribute to this meaningful mission.

Lines to the past

What began as measuring and control equipment manufacturing evolved into something extraordinary. The eighties marked our breakthrough into laser welding—initially solving our own production challenges, then rapidly expanding to serve customers facing similar precision demands.

1973

1987

1989

1994

1986

1997

1998

2000

2004

2006

2007

2008

2009

2011

2012

2013

2014

2015

2016

2017

2018

2020

2022

Masters in micromachining

- 30+ years of solid state laser know-how

- 15+ years of USP laser know-how

- Cleanroom (ISO7)

- Workshop (ISO8)

- Metallurgical/measuring facilities

- Stock of sheet metal and plastics

- ISO13485 certified

- 20+ laser systems

Complex problems.

Expert solutions.

Complex problems need expert solutions.

We’re ready to transform your design obstacles into competitive advantages.

Call us for straight answers and real solutions. Coffee’s on us.