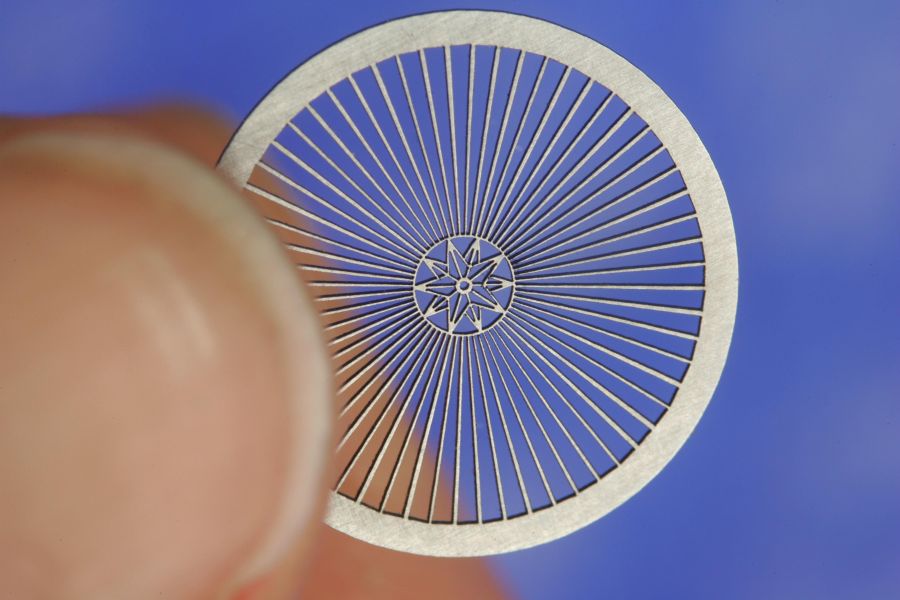

For complex shapes and patterns

Creating what conventional cutting can’t, from single pieces to thousands

Surgical accuracy

Perfect repeatability

Cost-efficient

Precision in every detail

Ultra-thin materials (0.005 mm to 1 mm) cut into extremely complex shapes and intricate patterns. From single prototypes to high-volume production with exceptional consistency in precision and quality.

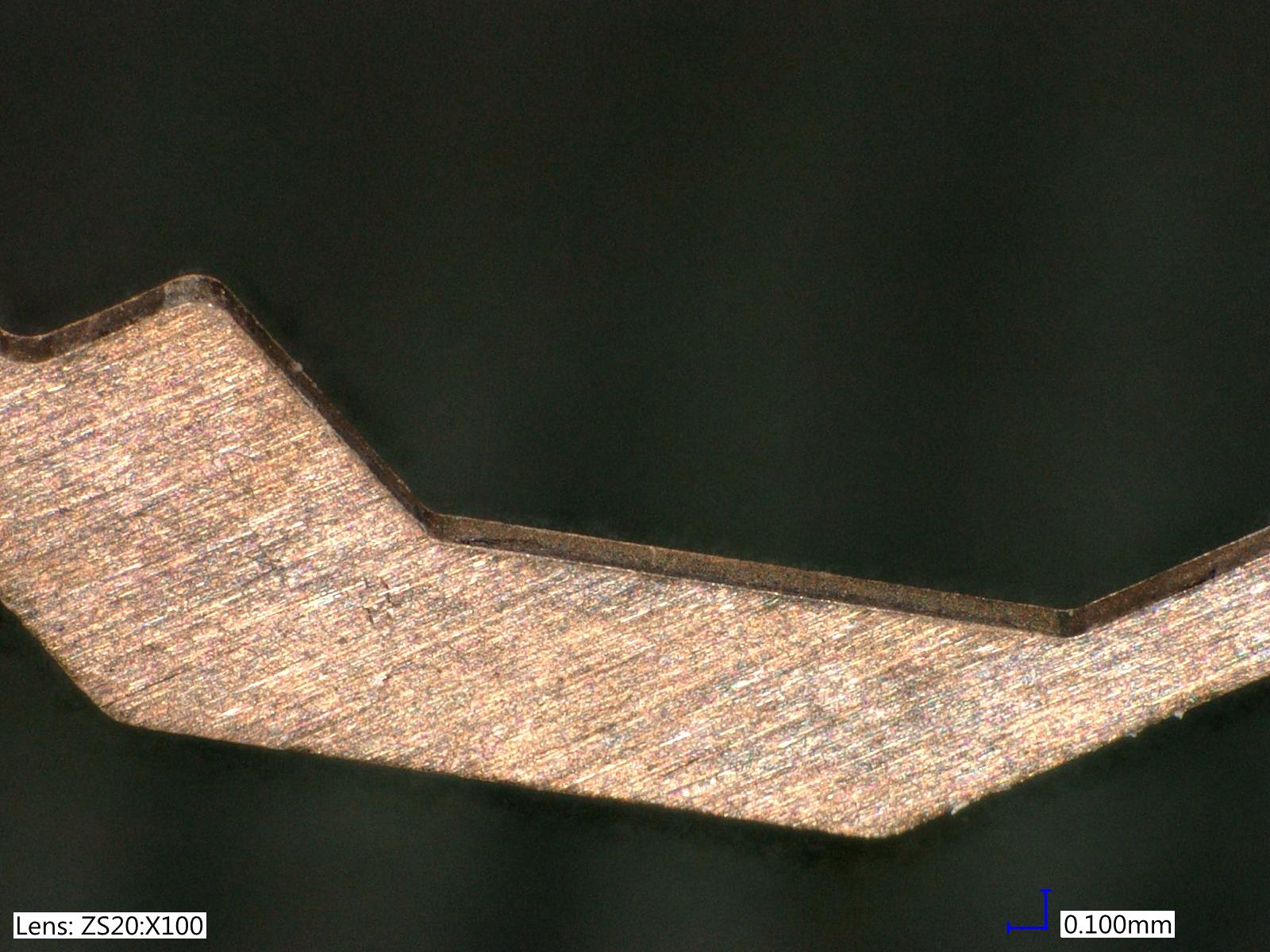

Industrial precision mastered

Medical devices, electronics, automotive components, jewelry – applications where accuracy is critical. Our laser cutters deliver the precision that demanding engineering requires.

Controlled processing. Exceptional precision.

Advantages that break conventional limits

- Surgical precision and accuracy

that defies physics - Infinite complexity

design freedom without boundaries - Perfect repeatability

identical results at production speed - Superior positional accuracy

optimization beyond limits - Minimal material waste

cost-efficiency through precision

Refined and

complex shapes

Ultra-thin materials (0.005 mm to 1 mm) transformed into complex shapes and patterns that conventional cutting methods struggle to achieve.

From prototypes to high-volume production with consistent precision.

Technical details

- Machining precision > 0,05 mm accuracy

- Narrow kerfs 20 µm. Minimal material loss

- Complex geometries 2D, 2.5D, 3D handling

- Cutting accuracy -3 µm to +3 µm

Materials mastered

Stainless steel • Titanium • Aluminum • Copper alloys • Plastics • Ceramics • Glass

Exotic capabilities

Tantalum • Molybdenum • Inconel

Nd:YAG laser advantage: superior cutting quality with exceptional metal interaction.

Cut through the complexity

Need precision that seems impossible? Patterns too complex for conventional methods?

We cut ultra-thin materials into shapes that break the rules. Call now.